Malolactic

fermentation (MLF) is a secondary bacterial fermentation that occurs in most

red wines. Oenococcus oeni, a member of the lactic acid bacteria (LAB)

family, is the primary bacterium responsible for MLF owing to its capacity to

withstand the severe circumstances of wine (high alcohol, low pH, and low

nutrition) and produce good wine sensory qualities.

One key purpose

of MLF is to provide microbiological stability for the subsequent metabolism of

L-malic acid. MLF specifically eliminates L-malic acid from wine, which can

serve as a carbon source for yeast and bacterial development, potentially

resulting in spoilage, spritz, and unpleasant flavours. MLF can also be used in

select wines to alter their character.

MLF can be

generated by inoculating a specific bacterial strain or happens spontaneously

during primary fermentation. Because natural or 'wild' MLF can be unpredictable

in terms of onset time and influence on wine quality, malolactic starter

cultures are widely employed.

This article

provides practical information for induction of MLF in red wine. Achieving

effective malolactic fermentation provides further practical instructions for

MLF induction, monitoring, and maintenance.

Essential parameters for a successful MLF in red wine.

- Composition of Red Wine or

Must.

Alcohol, pH,

temperature, and SO2 concentration are key wine compositional parameters

influencing MLF performance. Before beginning with MLF inoculation, it is

advised to test these parameters and make modifications as needed. Each of

these parameters has a range within which MLF is beneficial. As one or more of

these criteria grow unfavourable, the MLF will become more challenging (the

variables are cumulative). The table below summarises favourable and

unfavourable circumstances for MLF in red wine and provides further

explanation.

| Parameter | Favourable | Unfavourable |

|---|---|---|

| Ethanol (%v/v) | <14 | >16 |

| Temperature (℃) | 18 -22 | >16 - <25 |

| pH | 3.3-3.5 | <3.3 |

| Total SO2(mg/L) | <30 | >40 |

- Alcohol

The possible alcohol

concentration of red wine is an important factor to consider while inducing

MLF. It is advised that wines with a potential ethanol level more than 15-16%

v/v utilize an ethanol-tolerant strain of malolactic starting culture.

Furthermore, co-inoculation should be explored since it may help the bacteria

culture adapt to increased ethanol concentrations during fermentation. Consider

pre-adapting the starting culture to high ethanol conditions.

- Temperature

The optimal

growth temperature for LAB in grape juice is approximately 30°C. However, when

ethanol content increases, the optimal temperature decreases due to the harmful

effects of ethanol on bacteria at higher temperatures. Temperature should be

15-25°C (ideally 18-22°C when other factors are unfavourable and alcohol

concentration is about 10% v/v). Inoculation temperature is crucial as it is

the development stage that is most vulnerable to suboptimal temperatures.

Temperatures over 25°C slow down MLF, increasing the danger of bacterial

deterioration and volatile acidity. When using co-inoculation, it's important

to prevent high temperatures throughout the alcoholic fermentation process.

- pH

Higher pH

levels, especially over 3.5, promote growth of MLF bacteria and other spoilage

germs such as Pediococcus and Lactobacillus strains. To prevent

the formation of spoilage bacteria in red must and wines with pH levels above

3.5, consider co-inoculation and post-MLF stabilisation.

- SO2 concentration

Lactic acid

bacteria, particularly Oenococcus oeni, are extremely sensitive to the

molecular form of SO2. To prevent the harmful effects of molecular SO2 on

malolactic bacteria, it is recommended that must/wines for MLF induction have

no detectable free or molecular SO2. It is worth noting that traditional SO2

measurement methods in red wines, such as aeration-oxidation, can overestimate

free and molecular SO2 concentrations. Total SO2 content is a good indicator of

a wine's possible influence on malolactic bacteria and MLF, since bound SO2 may

hinder them.

Adding a maximum

of 50 mg/L total SO2 to grapes before crushing is not expected to negatively

impact MLF. However, due to the possibility of SO2 buildup from various

extrinsic (e.g., grape harvesting and shipping) and intrinsic (e.g., yeast

strains employed in alcoholic fermentation) sources, it is advised that an

accurate total SO2 measurement be performed prior to MLF induction.

For ideal MLF

conditions, young red wine should have a total SO2 level of less than 30 mg/L.

Total SO2 concentrations above 40 mg/L might delay or totally inhibit

malolactic fermentation (MLF), depending on the malolactic bacteria strain and

wine conditions. Concentrations above 50-60 mg/L may completely inhibit MLF.

- Other inhibitory factors

Pesticide

residues, elevated copper levels in the vineyard, and yeast-derived

medium-chain fatty acids can all impede MLF.

MLF strain selection criteria for red wine.

- Bacteria strain tolerance

When selecting a

malolactic starter culture, it's important to consider the strain's tolerance

to the physical and chemical conditions of the wine. This is especially true

when selecting a strain for red must/wine, where, for example, in wines with an

ethanol level of 15-16% v/v or more, the strains available are limited to those

with high alcohol tolerance.

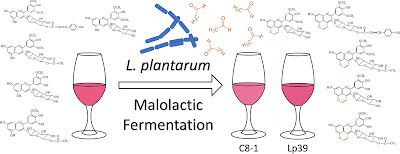

- Malolactic starter cultures for

red wine: Oenococcus oeni and Lactobacillus plantarum.

Commercial

malolactic starter cultures consist of many Oenococcus oeni strains,

each with unique sensitivities to various winemaking conditions and uses.

However, starter cultures of Lactobacillus plantarum, another member of

the wine lactic acid bacteria family, are becoming accessible for use in red

winemaking. Winemakers can use L. plantarum strains' specific

physiological features to induce MLF in red wines.

- Yeast-bacteria compatibility

The

compatibility of primary fermentation yeast with malolactic bacteria is a

significant determinant in the success or failure of MLF. Certain yeast strains

may block MLF by producing metabolites such as SO2 and certain fatty acids.

Using a yeast strain with high nitrogen demand, especially under low YAN must

circumstances, might deplete the nitrogen pool for malolactic bacteria. To

lessen yeast inhibitory effects on MLF in red wines, choose an appropriate

yeast/bacteria mix (according to supplier/manufacturer recommendations).

- Period of inoculation

Bacteria can be

inoculated at various phases of the winemaking process, with sequential and

co-inoculation being the most prevalent ways. Timing decisions may be

influenced by processing concerns and the type of starting culture employed.

Co-inoculation,

which involves inoculating malolactic bacteria at the beginning of alcoholic

fermentation (18-24 hours after yeast inoculation), is becoming increasingly

popular. Importantly, especially in red winemaking, co-inoculation may

potentially facilitate:

- A shorter overall fermentation time, which can lower the risk of spoilage by other microorganisms including Brettanomyces.

- Overcoming MLF problems associated with high ethanol levels and reduced nitrogen content at the end of primary ferment.

- Co-inoculation can improve the usage of particular Lactobacillus plantarum strains for MLF in red winemaking.

Lactic acid

bacteria are sensitive to SO2, hence when co-inoculation is performed, bacteria

should be added after yeast activity has been detected. After adding SO2, wait

at least 18-24 hours after inoculation to allow yeast to bind the free SO2.

Co-inoculation requires temperature management, especially in red wines where

high fermentation temperatures can harm both bacteria and yeast.

There may be

some risks associated with co-inoculation, including:

- Inhibition by high SO2 added during harvest/crushing

- Competition with yeast growth

- Antagonistic yeast/bacteria relationships (MLF strain compatibility is thus important.)

- Stuck primary ferments causing possible production of acetic acid from LAB.

In some red

winemaking applications, several timing choices might be employed. Delaying the

beginning of MLF, for example, may help to retain colour in lighter-colored red

wine varietals from colder winemaking locations. Furthermore, for certain

commercial preparations of Lactobacillus plantarum, the producer may

prescribe inoculation of a specific starter culture prior to the start of

alcoholic fermentation.

Role of Monitoring MLF in quality control parameter in red winemaking.

Monitoring MLF

completion is crucial for ensuring quality control in red wine production.

Regular assessment of L-malic acid content allows for correct commencement and

completion of MLF, as well as efficient post-MLF wine stabilisation (e.g., SO2

addition and pH adjustment).

Controlling MLF

with a chosen malolactic strain requires determining its onset. Regular

monitoring can easily establish the incidence of delayed or stalled MLF, and if

necessary, a rescue starting culture may be immediately deployed. This avoids

the dangers associated with uncontrolled proliferation of spoiling bacteria.

To determine MLF

completion, strive for a 'not found' malic acid result (<0.05 g/L by

enzymatic assay). However, a result of 0.1 g/L or fewer is low enough for the

MLF to be regarded nearly complete and to reduce the danger of MLF spoiling

after bottling. Precise monitoring of MLF completion reduces the possibility of

uncontrolled growth of other wine microorganisms, as well as spoiling. Delays

in post-MLF wine stabilisation, in particular, can result in increases in

volatile acidity and other spoiling events. Wines are susceptible to oxidation

and spoiling from microbes including acetic acid bacteria and Brettanomyces.

Accurate identification of MLF completion is therefore critical in preventing

such spoilage and quality degradation.

Co-inoculation

can lead to MLF completion before alcoholic fermentation. In such instances, it

is advised that post-MLF wine stabilisation be carried out once alcoholic

fermentation is complete.

References

- Howe, P.A., Worobo, R., Sacks, G.L. 2018. Conventional measurements of sulfur dioxide (SO2) in red wine overestimate SO2 antimicrobial activity. Am. J. Enol. Vitic. 69: 210-220.

- Nordestgaard, S. 2019. AWRI Vineyard & Winery Practices Survey.

- Coelho, JM., Howe, P.A., Sacks, G.L. 2015. A headspace gas detection tube method to measure SO2 in wine without disrupting SO2 equilibria. Am J. Enol. Vitic. 66: 257-265.

No comments:

Post a Comment